Level measurement plays a vital role in the safe and efficient operation of chemical plants and oil & gas facilities.

Whether monitoring storage tanks, reaction vessels, separators, or pipelines, knowing the exact level of liquids and slurries helps prevent overflows, ensures accurate inventory management, and protects both personnel and equipment.

Because these industries often involve corrosive chemicals, explosive atmospheres, extreme temperatures, and high pressures, level transmitters used here must be highly reliable, rugged, and compliant with strict safety standards.

This article explores the main types of level transmitters used in these industries, their applications, and the importance of hazardous-area certification such as ATEX.

Chemical Industry Instrumentation

The chemical industry handles a wide range of media such as acids, alkalis, solvents, resins, and slurries. These can be toxic, corrosive, or reactive. Therefore, chemical industry instrumentation requires special design considerations, including:

- Chemical compatibility of wetted parts

- Resistance to corrosion and abrasion

- Ability to withstand extreme process temperatures

- Non-contact measurement options for aggressive media

- Safety approvals for hazardous zones

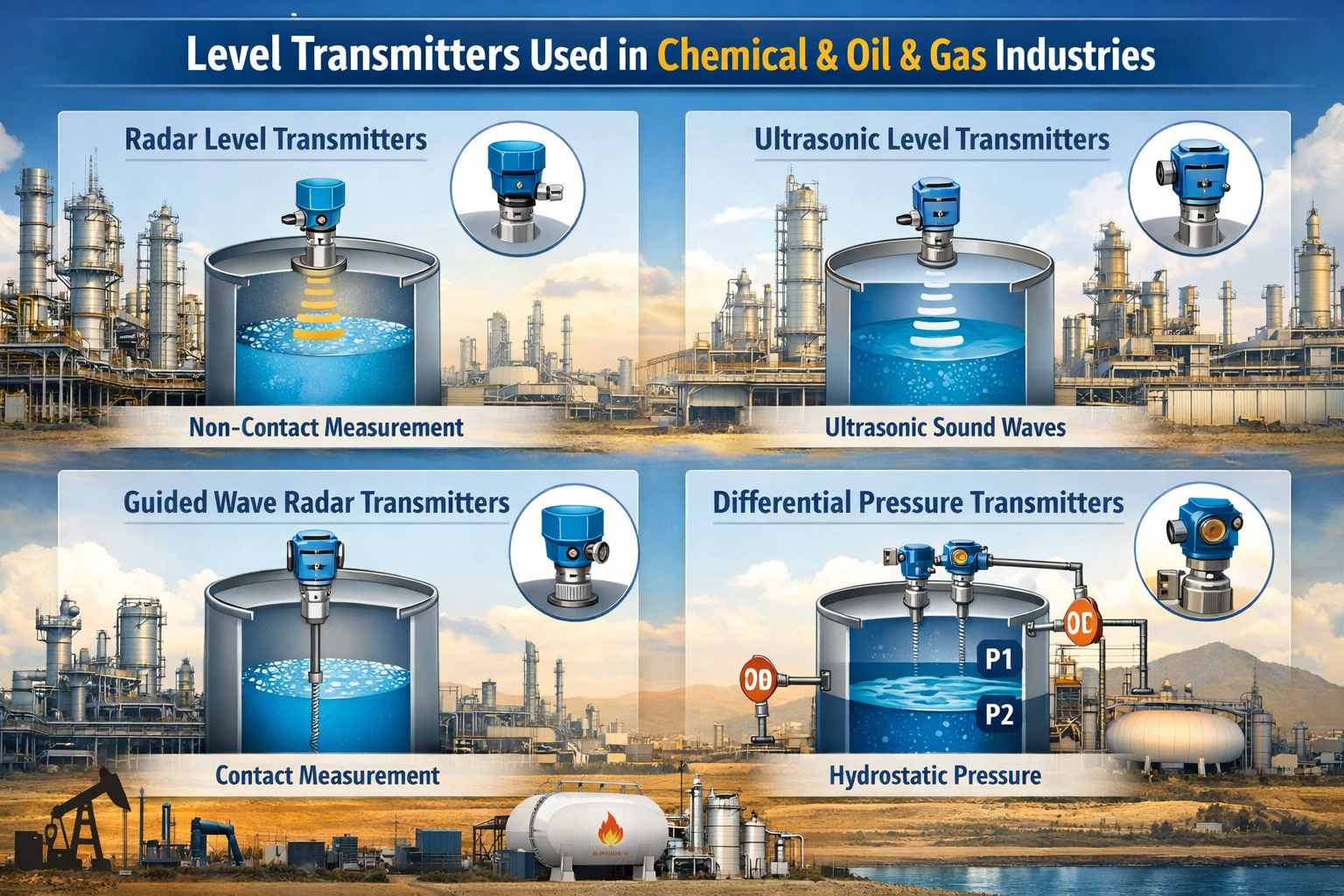

Common level transmitter technologies used

- Hydrostatic level transmitters

These measure pressure due to the liquid column and are often used in storage tanks, reactors, and day tanks. Diaphragms are typically made from Hastelloy, PTFE, or ceramic to resist chemical attack. - Ultrasonic level transmitters

Ideal for non-contact measurement, especially where the medium is corrosive or crystallizing. They are used widely for open tanks, effluent pits, and chemical dosing systems. - Radar level transmitters

Both non-contact radar and guided wave radar are used in chemical processes. Radar technology works well with vapors, foam, and high temperatures, making it suitable for distillation columns and solvent storage tanks. - Capacitive level transmitters

Suitable for liquids and some bulk solids. They are often used when the dielectric constant of the medium remains predictable.

Why level measurement matters in chemical plants

- Prevents tank overflows and spillage

- Ensures correct chemical reaction ratios

- Enables safe storage of hazardous materials

- Supports automated process control

- Helps meet environmental and safety regulations

Because chemicals can be explosive, flammable, or highly reactive, instrumentation failure can lead to major accidents. Therefore, robust level transmitter design and certification are essential.

Oil and Gas Level Measurement

In the oil and gas sector, level measurement is critical from exploration and drilling to refining and distribution. Media encountered include crude oil, produced water, condensate, LNG, LPG, slurries, and sludge. Conditions are often harsh: high pressure, high temperature, vibration, and outdoor exposure.

Application areas

- Refinery storage tanks

- Separators and dehydrators

- Offshore platforms

- Floating roof tanks

- Pipeline surge vessels

- LNG and cryogenic tanks

- Sump pits and flare knock-out drums

Technologies commonly used in oil & gas level measurement

- Radar level transmitters

Radar is the most preferred technology due to its accuracy and immunity to process conditions. It works effectively in vapor, steam, changing densities, and high pressures. FMCW radar and guided wave radar are especially common. - Differential pressure transmitters

Widely used to measure liquid level in pressurized vessels. Seal systems or capillaries isolate the process fluid and protect the transmitter. - Magnetic level gauges and transmitters

Often used where visual indication is required along with electronic output. They are reliable in high-pressure and high-temperature environments. - Ultrasonic and vibration-based level instruments

Common in wastewater pits and produced water systems. - Capacitance and RF admittance level transmitters

Used for interface measurement such as oil-water separation.

Accurate level measurement prevents:

- Tank overfill and hydrocarbon release

- Pump cavitation

- Damage to separation equipment

- Loss of product and revenue

- Environmental contamination

Hazardous Area Transmitters

Both chemical and oil & gas facilities frequently operate in locations where flammable gases, vapors, or dusts may be present. These are classified as hazardous areas, typically divided into Zones or Classes depending on international standards.

A hazardous area transmitter is designed to operate safely under these conditions without becoming an ignition source. This is achieved by protective methods such as:

- Intrinsic safety (energy-limited circuits)

- Explosion-proof or flameproof housings

- Increased safety enclosures

- Pressurization or purging systems

These transmitters undergo rigorous testing to ensure they will not ignite explosive atmospheres even in fault conditions.

Where hazardous area transmitters are used

- Oil refineries

- Chemical blending and processing units

- Petrochemical storage farms

- LNG facilities

- Offshore platforms

- Gas compressor stations

- Tanker loading terminals

Using non-certified instruments in these locations is not only unsafe but typically illegal.

ATEX Certified Instruments

In Europe and many other regions, explosive atmosphere safety is governed by ATEX Directive (ATmosphères EXplosibles). Instruments bearing ATEX certification are tested to perform safely in explosive environments.

Why ATEX certification matters

- Meets legal compliance for hazardous locations

- Reduces risk of fire and explosions

- Ensures device integrity during faults

- Provides confidence in product reliability

- Required by insurance and regulatory authorities

ATEX-certified level transmitters are designed for Zone 0, Zone 1, or Zone 2 environments depending on risk level. Similar certifications include IECEx, FM, and UL, commonly used in other regions.

Features often found in ATEX-level transmitters

- Rugged explosion-proof housings

- Intrinsically safe input/output circuits

- High ingress protection (IP 66 / IP 68)

- Corrosion-resistant materials

- Temperature-resistant electronics

Choosing the Right Level Transmitter for Chemical & Oil & Gas Applications

Selecting the right instrument requires understanding the process medium, tank geometry, safety zone classification, and environmental conditions. Engineers typically evaluate:

- Type of material (liquid, slurry, foam, vapor, solid)

- Operating temperature and pressure

- Corrosive or abrasive nature

- Presence of vapors or turbulence

- Contact vs non-contact requirement

- Required level accuracy

- Certification needed (ATEX, IECEx, SIL, etc.)

For corrosive chemicals, non-contact radar or ultrasonic sensors are often preferred. For high-pressure separators, differential pressure or guided wave radar are common choices.

Cryogenic LNG tanks typically use radar level transmitters due to reliability in extreme cold.

Conclusion

Level transmitters used in the chemical and oil & gas industries must combine accuracy, durability, and stringent safety compliance.

Chemical plants require corrosion-resistant, reliable instruments capable of handling aggressive media, while oil & gas facilities demand transmitters that can withstand extreme pressures, temperatures, and hazardous environments.

Hazardous area transmitters and ATEX-certified instruments play a crucial role in preventing explosions and ensuring safe plant operation.

By understanding process conditions and regulatory requirements, engineers can select the most suitable level transmitter technology, ensuring efficient production, environmental protection, and safety of personnel.