Imagine the intricate ballet of a modern industrial plant—pipelines humming, tanks bubbling, machinery whirring. What ensures this complex dance proceeds safely and efficiently? Often, it’s the silent vigilance of a pressure transmitter. These versatile instruments are the eyes and ears of countless systems, converting physical forces into actionable data that drives process control and safety.

This comprehensive guide will demystify the pressure transmitter working principle, explore various pressure transmitter types, and highlight their indispensable role in modern industry. From ensuring safety to optimizing efficiency, pressure transmitters are the unsung heroes of process control, providing the critical information needed to manage everything from fluid flow to gas density.

What Exactly is a Pressure Transmitter? A Core Definition

At its heart, a pressure transmitter is a device used to measure pressure and convert it into an electrical signal. This electrical signal can then be used to display readings, or sent to a control system like a Programmable Logic Controller (PLC) or Distributed Control System (DCS) for further processing.

The output of a pressure transmitter is typically a standardized analog electrical signal, such as a current range of 4 to 20 mA or a voltage range of 0 to 10 VDC, which represents the 0 to 100% of the sensed pressure range. This signal can also be digital. Common units for pressure measurement include pascal (Pa), bar, atmosphere (atm), and psi (pounds per square inch).

Transducer vs. Transmitter: Clearing the Confusion

While often used interchangeably, it’s helpful to distinguish between a transducer and a transmitter:

- A transducer is a device that converts one form of energy to another. For example, a pressure transducer converts the sensed pressure into an analog electrical signal, often with a millivolt output.

- A transmitter then takes this initial electrical signal from the transducer and converts it into a larger, more robust electrical signal that can be sent over long distances to a control system. Therefore, a pressure transmitter is an instrument connected to a pressure transducer.

The Ingenious Pressure Transmitter Working Principle: How it Converts Pressure to Signal

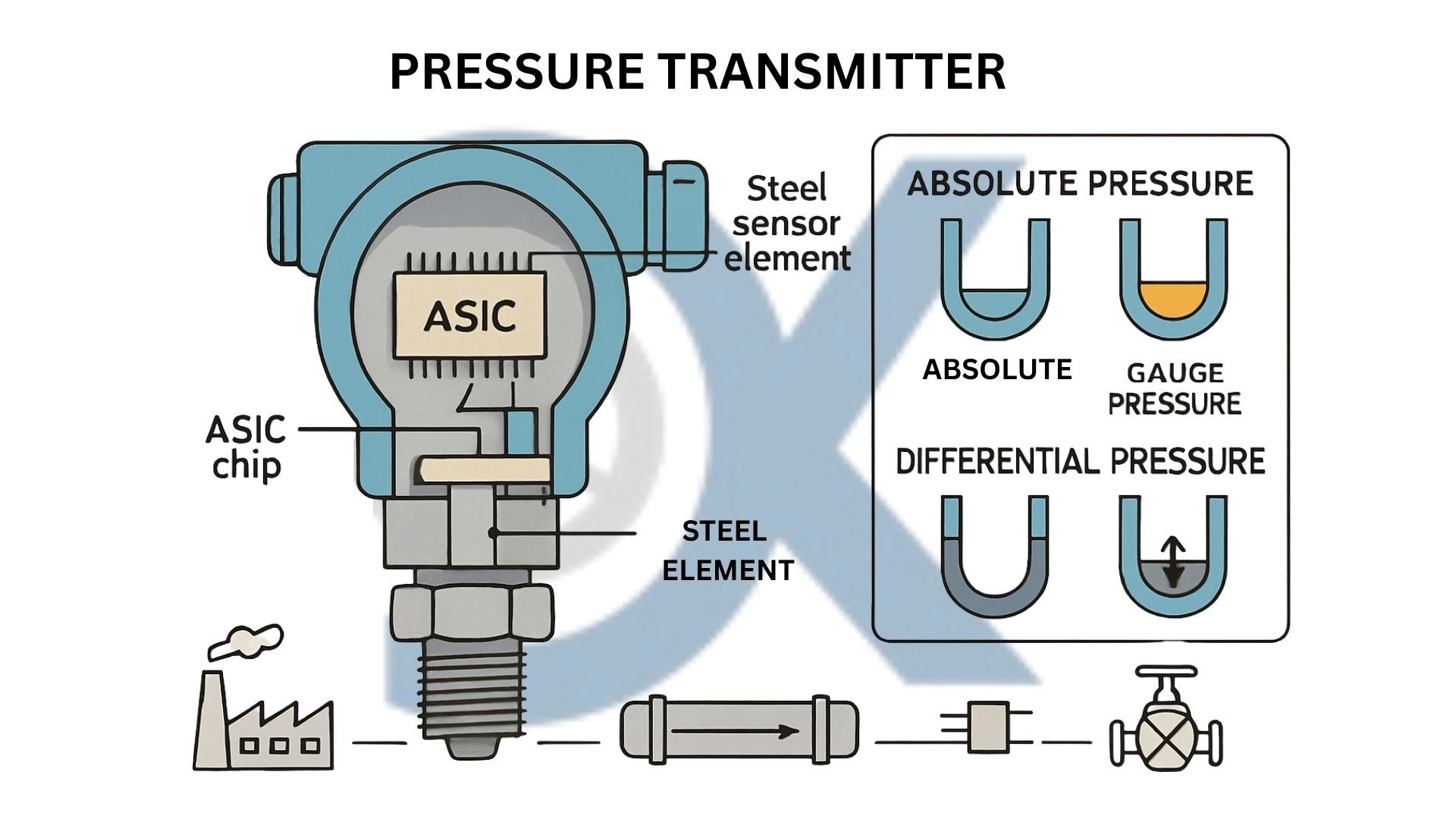

To grasp the magic behind these devices, it’s essential to understand the pressure transmitter working principle, which hinges on two key elements: the pressure sensor and an application-specific integrated microchip (ASIC).

The Pressure Sensor in Action

The pressure sensor is the first point of contact with the medium whose pressure is being measured.

- Thin-Film-on-Steel Cells: Many advanced sensors, such as those used by Trafag, employ thin-film-on-steel cells. Here, resistance bridges, or strain resistors, are applied as an extremely thin film (just a few atomic layers thick) onto a steel sensing element.

- Membrane Deformation: When pressure is applied to the sensor, its membrane deforms at predefined points.

- Wheatstone Bridge Principle: Crucially, the resistors are placed at these deformation points. As the membrane deforms, two resistors are compressed, and two are stretched. This change in physical shape alters their electrical resistance. These four resistors typically form a Wheatstone bridge, where the change in resistance generates a measurable voltage signal.

- Temperature Influence: The raw electrical signal generated by this process is often non-linear and highly susceptible to ambient temperature changes, as temperature significantly influences the resistance of the bridge.

The Role of the Application Specific Integrated Microchip (ASIC)

To transform that raw, temperature-sensitive signal into a reliable measurement, intelligent electronics are required. This is where the Application Specific Integrated Microchip (ASIC) comes into play:

- Correction and Amplification: The ASIC corrects and amplifies the measurement signal, turning a small 10-millivolt signal, for example, into a much more substantial 10-Volt signal.

- Temperature Compensation: During manufacturing, correction values are meticulously determined and stored individually for each pressure transmitter. This involves applying precisely defined pressures and measuring the resulting signals across a range of different temperatures. This process allows the ASIC to apply specific correction values to achieve optimal temperature compensation, resulting in a linear, accurate, and temperature-independent measurement signal across the entire operating pressure and temperature range.

- Standardized Output: The ASIC ultimately generates a standardized measurement signal that can be reliably transmitted to higher-level control systems. Manufacturers like Trafag ensure optimal function and reliability by developing both the measuring cell and the ASIC under one roof, guaranteeing a precise match between the two key components.

Decoding Pressure Transmitter Types: Understanding the Variety

Understanding the different pressure transmitter types is crucial for selecting the right instrument for any application. They are primarily categorized by the type of pressure they measure and the underlying sensor technology.

Categorization by Pressure Measurement Type

- Absolute Pressure Transmitters: Measure pressure relative to a perfect vacuum (0 psi(a)). These are vital in vacuum systems and industries like chemical and pharmaceutical, where precise measurements against a true zero reference are critical. Fuji Electric offers models like the FKA.

- Gauge Pressure Transmitters (Manometric Pressure): Measure pressure relative to current atmospheric pressure (0 psi(g)). This is the most common type, widely used in HVAC, pneumatic, hydraulic systems, and in the oil and gas industry to monitor pipeline pressures. Fuji Electric’s FKG is an example of this type.

- Differential Pressure Transmitters: These versatile devices measure the difference in pressure between two distinct points. Differential pressure transmitters are extensively used for measuring fluid flow, liquid levels, density, and viscosity. Fuji Electric produces differential pressure transmitter models like the FKC.

- Multivariable Pressure Transmitters: These advanced devices measure multiple parameters—such as pressure, temperature, and flow rate—using a single unit. They offer a cost-effective solution in industries requiring simultaneous measurement of various parameters, like the chemical and petrochemical sectors.

Categorization by Sensor Technology

The choice of sensor technology is dictated by the specific application and environmental conditions.

- Piezoresistive (Strain Gauge) Pressure Transmitters: The most common type, these sensors rely on the principle that the electrical resistance of a material changes when subjected to mechanical strain from applied pressure. Thin-film-on-steel cells are a prime example.

- Capacitive Pressure Transmitters: These sensors measure changes in capacitance between two plates as pressure deforms a diaphragm, altering the distance between them. They are used in diverse sectors including oil & gas, energy, and food & beverage.

- Piezoelectric Pressure Transmitters: These sensors generate an electrical charge directly when subjected to mechanical pressure.

- Thin-Film Resistive Pressure Transmitters: Utilizing an extremely thin layer of resistive material, these are highly sensitive to pressure changes, essential for accuracy and precision in industrial solutions.

- Optical Pressure Sensors: These sensors use optical fibers, where light properties change in response to pressure, allowing for accurate determination. They are utilized in hydraulic systems and gas pipelines.

- Hydrostatic Pressure Transmitters: Primarily used for level measurement, these transmitters operate on the hydrostatic principle, providing a pressure measurement proportional to the fluid’s head. They are common in tanks and reservoirs.

The Lifeline of Industry: Applications of Pressure Transmitters

Pressure transmitters are indispensable tools that enhance safety, reliability, and efficiency across numerous industries.

- Process Industries: Widely used in sectors such as oil and gas, chemical, food and beverage, and water treatment and refining. They monitor and control pressure in pipelines, tanks, and vessels, ensuring process safety, reducing downtime, and enabling fluid control and monitoring.

- Automotive Industry: Employed for measuring pressure in tires, engine oil, fuel, and air, as well as within hydraulic systems like brakes and suspension.

- Aerospace and Aviation: Critical for measuring altitude, airspeed, and cabin pressure, and for monitoring hydraulic systems and fuel tanks in aircraft.

- Marine Applications: Used in offshore oil and gas exploration, shipping, and fishing to measure the pressure of seawater, oil, and gas, and liquid levels in vessels and tanks.

- Specific Measurement & Control Tasks: Pressure measurement and control, monitoring critical processes, tank filling level measurement and control, fluid flow measurement, process safety, pressure leak detection, and pump control systems are all common applications.

Ensuring Reliability: Pressure Transmitter Calibration

Pressure transmitter calibration is a crucial aspect of ensuring the accuracy and reliability of these devices.

- Why Calibration is Crucial: For precise and reliable pressure measurement, especially in critical applications, pressure transmitter calibration is paramount. Calibration verifies how closely the transmitter’s output matches the actual pressure being measured.

- Accredited Services: Companies like Trafag offer SCS-certified calibration laboratories that operate in accordance with ISO 17025 standards. These accreditations emphasize expertise and efficient service, ensuring the highest level of calibration accuracy.

- Annual Requirement: For critical pressure applications, annual calibration of pressure transmitters is often required to maintain precision and accuracy over time. For example, a transmitter might be calibrated to provide a 4 to 20 mA current range for a 0 to 350 psi process pressure range.

- In-Factory Precision: As noted in the pressure transmitter working principle, during manufacturing, correction values are meticulously determined and stored individually in each transmitter by applying precisely defined pressures and measuring the signals at different temperatures. This ensures an accurate and temperature-compensated output.

How to Choose the Right Pressure Transmitter: Key Considerations

Selecting the optimal pressure transmitter type for a specific application requires careful consideration of several factors.

- Accuracy: This refers to how closely the transmitter’s output matches the actual pressure. It’s typically expressed as a percentage of the full-scale range (e.g., ±0.5%). High accuracy is essential for many industrial solutions.

- Pressure Range: This defines the minimum and maximum pressure the transmitter can measure. It’s crucial to choose a range appropriate for the specific application; a range that is too small may not measure the required pressure, while a range that is too large can compromise accuracy.

- Stability: Stability indicates how well the transmitter maintains its accuracy over time, usually expressed as a percentage of the full-scale range per year. This is important where pressure changes slowly over extended periods.

- Application and Environment: The specific conditions (e.g., media, temperature, vibration, corrosive atmospheres) heavily influence the choice of sensor technology and overall transmitter design. Industrial pressure transmitters are generally more accurate and durable than consumer products, a worthwhile investment for precise measurement.

Advanced Insights & Best Practices for Pressure Transmitter Deployment

While the sources focus on the core functionality, they hint at the importance of proper deployment for long-term reliability.

- Installation Best Practices: The careful installation of a pressure transmitter is key. This includes proper mounting, ensuring vibration isolation, and correctly configuring impulse lines (the tubing connecting the process to the transmitter) to prevent issues like liquid traps or blockages.

- Troubleshooting Common Issues: Pressure transmitters are used for “diagnostic purposes, to help solve problems in the industrial process”. Understanding common symptoms of malfunction (e.g., erratic readings, no output) and basic diagnostic steps can significantly reduce downtime.

- Smart Transmitters and Digital Communication: Modern transmitters go “beyond analog” by incorporating digital communication protocols like HART, FOUNDATION Fieldbus, and Profibus. These enable remote configuration, enhanced diagnostics, and multi-variable data transmission, seamlessly integrating with modern control systems and contributing to Industrial Internet of Things (IIoT) initiatives for predictive maintenance and optimization.

Considering Brands & Manufacturers

The market for pressure transmitters is robust, featuring many reputable manufacturers. For instance, Trafag is noted for producing its own measuring cells and ASICs, guaranteeing optimal function and reliability. Fuji Electric offers a wide range of pressure transmitter types, including differential pressure transmitters (FKC), absolute (FKA), and gauge (FKG) models. Process Parameters also offers a selection of pressure and level sensors, including ATEX IECEX certified models.

FAQ's

What is a pressure transmitter?

A pressure transmitter is a device used to measure pressure and convert it into a standardized electrical signal (like 4-20 mA or 0-10 VDC). This signal can then be transmitted to a control system or display device for monitoring and control.

How does a pressure transmitter work? What is its working principle?

The pressure transmitter working principle involves two main elements: a pressure sensor and an application-specific integrated microchip (ASIC). The pressure sensor, often a thin-film-on-steel cell, deforms under pressure, changing the resistance in a Wheatstone bridge and generating a raw electrical signal. The ASIC then corrects and amplifies this signal, performing temperature compensation to produce a linear, accurate, and temperature-independent output signal.

What is the difference between a pressure sensor, a pressure transducer, and a pressure transmitter?

While often confused, they have distinct roles:

- A pressure sensor usually provides a millivolt output signal.

- A pressure transducer converts a physical variable into an analog electrical signal and offers an amplified voltage output.

• A pressure transmitter takes the transducer’s signal and converts it into a larger, standardized electrical signal (typically 4-20 mA) for long-distance transmission to a control system. A pressure transmitter is an instrument connected to a pressure transducer.

What are the different types of pressure transmitters?

Pressure transmitters can be categorized by the type of pressure they measure or by their sensor technology:

- By Pressure Measurement: Absolute, Gauge, and Differential pressure transmitters are the main types. There are also multivariable pressure transmitters that measure multiple parameters like pressure, temperature, and flow rate.

- By Sensor Technology: Common types include piezoresistive (strain gauge), capacitive, piezoelectric, thin-film resistive, optical, and hydrostatic sensors.

What is a differential pressure transmitter used for?

A differential pressure transmitter measures the difference in pressure between two distinct points. Its versatility allows it to be used for measuring fluid flow, liquid levels, density, and viscosity, as well as pressure differences in pipes.

Why is pressure transmitter calibration important?

Pressure transmitter calibration is crucial to ensure the accuracy and reliability of the device over time. For critical applications, annual calibration may be required to maintain precision. Calibration ensures the transmitter’s output precisely matches the actual pressure being measured. Specialized accredited calibration laboratory services, such as those that comply with ISO 17025 standards, are available for this purpose.

What are the main applications of industrial pressure transmitters?

Pressure transmitters are essential across many industries, including:

- Process Industries: Oil & gas, chemical, food & beverage, water treatment.

- Automotive Industry: Tire pressure, engine oil, fuel, and hydraulic systems.

- Aerospace and Aviation: Altitude, airspeed, cabin pressure, and monitoring hydraulic/fuel systems.

- Marine Applications: Seawater, oil, and gas pressure, and liquid levels in vessels and tanks. They are used for pressure measurement and control, monitoring critical processes, level control, fluid flow measurement, and process safety.

What factors should I consider when choosing a pressure transmitter?

When selecting a pressure transmitter type, consider three key factors:

- Accuracy: How closely the output matches the actual pressure.

- Pressure Range: The minimum and maximum pressure the transmitter can measure, ensuring it’s appropriate for your application.

- Stability: How well the transmitter maintains its accuracy over time. The specific application and environment will also dictate the best sensor technology and overall design. Industrial transmitters are generally more accurate and durable than consumer products.

Does the blog mention specific brands like WIKA?

The provided sources do not contain specific information about “Pressure transmitter WIKA.” However, the industry features many reputable manufacturers, such as Trafag (known for developing its own measuring cells and ASICs for optimal quality) and Fuji Electric (offering various models like FKC, FKA, and FKG). When evaluating any brand, always consider your specific application requirements, product specifications, certifications, and manufacturer support

2 thoughts on “What is a Pressure Transmitter?”

Hey Kuncham

Pingback: A Complete Guide to the Various Types of Pressure Transmitters - Kuncham Blogs

Comments are closed.