In the world of fluid dynamics and industrial automation, precision is everything. Systems that carry water, gas, or steam must run reliably to avoid costly downtime or safety risks. Behind the scenes, small but powerful devices make this possible—and one of the most important is the flow switch.

Whether you’re in HVAC, fire safety, or industrial operations, a flow switch plays a critical role in keeping systems safe and efficient. In this guide, we’ll break down the flow switch working principle, the types of flow switches, their applications, and best practices for installation and maintenance.

How Does a Flow Switch Work?

At its core, a flow switch is designed to monitor the flow rate of a liquid, gas, or steam inside a pipeline or duct. Unlike a simple flow meter that only measures, a flow switch goes a step further: it can initiate an action when the flow reaches a certain point.

For example:

- If the flow drops below a safe limit, the switch can shut down a pump to prevent overheating.

- If the flow suddenly increases, it might trigger an alarm to alert operators.

That’s why flow switches are often called the “gatekeepers” of fluid systems.

The Flow Switch Working Principle

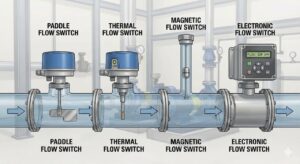

The working principle of a flow switch depends on how it senses motion inside the system. Let’s look at the standard designs:

1. Paddle Flow Switches

These are among the most widely used. A paddle is placed inside the pipe, and when fluid pushes against it, the paddle moves. That movement triggers a reed switch (a tiny magnetic switch), which then sends an electrical signal.

2. Piston or Shuttle Flow Switches

A magnetic piston moves back and forth with the flow of liquid. As it shifts, it activates an external reed switch. A spring ensures the piston returns to its original position when the flow stops. These are great for clean liquids in cooling and lubrication systems.

3. Solid-State Flow Switches

Instead of moving parts, solid-state switches work on the thermal dispersion principle. Two sensors measure heat: one acts as a reference, while the other is heated. When fluid flows, it carries heat away faster, and the sensor detects this change. Since there are no mechanical parts, these switches are highly accurate and low-maintenance.

4. Specialised Switches

Ultrasonic flow switches bounce sound waves through the fluid to detect movement—ideal for hazardous or contaminated fluids.

Other specialised versions include gas flow switches, volumetric flow switches (measuring litres per minute), and velocity switches (measuring meters per second).

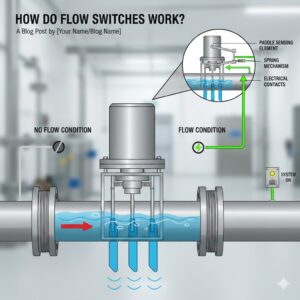

Flow Switch Diagram: A Simple View

A flow switch diagram helps visualise how it integrates into a control system.

- The switch sits inside the pipeline.

- When the flow reaches a set point, the switch’s contacts change (Normally Open → Closed or vice versa).

- This action completes an electrical circuit, which can power a pump, trigger a relay, or activate a safety mechanism.

- Overcurrent protection is usually added to keep the system safe.

In short: movement of fluid → mechanical/electronic signal → control action.

Types of Flow Switches: Choosing the Right One

No single flow switch fits every situation. Choosing depends on the medium, the accuracy needed, and the environment.

- Mechanical Flow Switches – Reliable and widely used in HVAC, water treatment, and fire protection.

- Paddle Flow Switches

- Piston/Shuttle Flow Switches

- Solid-State Flow Switches – No moving parts, perfect for clean liquids and gases where sensitivity and low maintenance matter.

- Specialised Flow Switches – Ultrasonic, volumetric, velocity, and gas/liquid-specific switches designed for niche applications.

Where Are Flow Switches Used?

Flow switches are found across many industries:

- Pump Protection (Dry Run Prevention): Stops pumps from overheating when the water supply fails.

- HVAC and Boilers: Ensures proper flow before a boiler ignites or a chiller starts, preventing freeze damage.

- Industrial Systems: Keeps cooling and lubrication lines running to protect machinery.

- Sanitary Systems: Stainless-steel flow switches are vital in food, pharma, and medical industries, where hygiene is critical.

Installation & Maintenance: Best Practices

A flow switch is only as good as its installation. Follow these tips:

- Install on straight pipe runs: Ideally, 10 pipe diameters upstream and downstream to avoid turbulence.

- Avoid bends and valves nearby: These cause erratic readings.

- Check wiring configuration: Know whether you need Normally Open (NO) or Normally Closed (NC) contacts.

Maintenance & Troubleshooting

- Mechanical issues: Scale buildup, corrosion, or debris can block moving parts.

- Testing:

- Visual check – see if the switch activates when the flow starts/stops.

- Electrical check – use an ohmmeter to confirm continuity.

Regulatory testing: In fire safety systems, periodic testing is a legal requirement.

How to Choose the Right Flow Switch

Before buying, consider:

- Pipe size & flow rate – Does it match your system requirements?

- Fluid type & material compatibility – Brass, stainless steel, or plastic may be needed depending on the medium.

- Electrical requirements – Voltage rating, NO/NC configuration, and relay compatibility.

- Type flow switches price – Mechanical switches are generally cheaper, while solid-state and ultrasonic options come at a higher cost but require less maintenance

Final Thoughts

A flow switch may be small, but it plays a massive role in ensuring safety, efficiency, and reliability in fluid systems. By understanding the types of flow switches, their working principles, diagrams, and uses, you can make better choices for your system and prevent costly failures.

FAQs About Flow Switches

What is a flow switch?

A flow switch sensor is a device that monitors liquid, gas, or steam flow in a pipeline. Unlike a meter, it can trigger actions such as shutting down pumps or activating alarms when flow reaches a set point.

How does a flow switch work?

The flow switch working principle is simple: fluid motion moves a paddle or piston (or changes heat in a sensor), which then activates an electrical switch to control connected equipment.

How is a flow switch different from a flow meter?

A flow meter only measures and displays flow data. A flow switch can act—shutting down pumps, starting fans, or triggering alarms.

What are the main types of flow switches?

- Paddle flow switches

- Piston/shuttle flow switches

- Solid-state flow switches

- Specialised ultrasonic, volumetric, or velocity switches

What are common uses of flow switches?

They are widely used in pump protection, HVAC systems, boilers, industrial cooling/lubrication, and sanitary processes.

Where should a flow switch be installed?

On a straight section of pipe, away from bends or valves, with about 10 pipe diameters of straight run on both sides for accuracy.

How do you test a flow switch?

- Visual test: Check if the switch activates correctly when the flow changes.

- Electrical test: Use an ohmmeter to confirm circuit continuity.

8 thoughts on “What is a Flow Switch?”

Crazywincasino, man, it’s legit! They got all the slots I love and the live dealer games are intense. Give it a whirl!crazywincasino.

naturally like your website however you need to test the spelling on several of your posts. Many of them are rife with spelling problems and I find it very troublesome to inform the reality however I’ll definitely come back again.

I’ve heard some good things about wagipluss. Anyone tried it? Looks promising for online gaming. Planning to give it a shot this weekend.

Definitely believe that which you stated. Your favorite justification appeared to be on the internet the easiest thing to be aware of. I say to you, I certainly get irked while people consider worries that they just do not know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side-effects , people can take a signal. Will probably be back to get more. Thanks

Wow! Thank you! I permanently needed to write on my blog something like that. Can I take a portion of your post to my site?

Some truly good info , Gladiolus I observed this. “Carthago delenda est. (Carthage must be destroyed.)” by Marcius Porcius Cato.

Can I simply say what a relief to find somebody who truly is aware of what theyre speaking about on the internet. You undoubtedly know the way to deliver a difficulty to gentle and make it important. More folks need to learn this and understand this side of the story. I cant believe youre no more fashionable because you positively have the gift.

Have you ever thought about publishing an e-book or guest authoring on other websites? I have a blog centered on the same subjects you discuss and would really like to have you share some stories/information. I know my subscribers would enjoy your work. If you are even remotely interested, feel free to shoot me an e-mail.