Flow switches are essential components in industrial plants because they monitor, detect, and control the movement of liquids and gases through pipelines and process systems.

These devices help protect equipment, ensure safety, maintain product quality, and optimize energy consumption.

By sending signals when flow rates change or fall outside normal ranges, flow switches prevent pump damage, overheating, leaks, and system failures.

Industrial facilities such as chemical plants, oil refineries, water treatment stations, HVAC systems, and power plants use different types of flow switches based on the nature of the fluid, flow rate, pressure, temperature, and application needs.

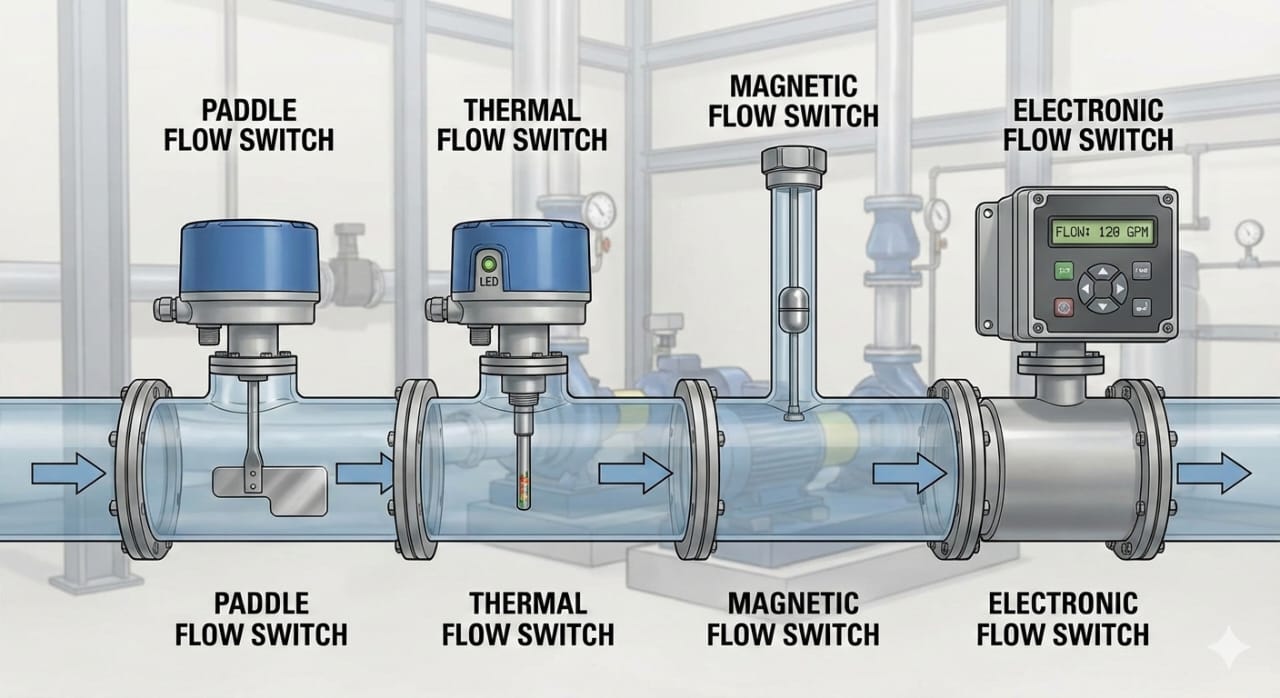

This article explains the most common flow switch types used in industrial plants, focusing on paddle flow switches, thermal flow switches, magnetic flow switches, electronic flow switches, and industrial flow sensors.

Paddle Flow Switch

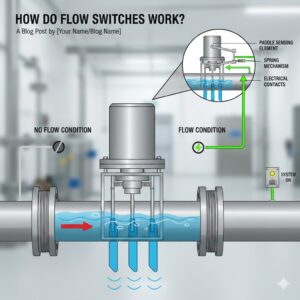

A paddle flow switch, also known as a vane-type flow switch, is one of the simplest and most widely used designs in industrial applications. It consists of a paddle or vane inserted into the pipeline. When fluid flows through the pipe, it exerts force on the paddle, causing it to move. This movement activates a mechanical or magnetic switching element that sends a signal indicating that flow is present.

Paddle flow switches are especially common in:

- HVAC chilled and hot water systems

- Fire protection systems

- Cooling water circulation

- Pump protection applications

They are ideal when the fluid is relatively clean and the flow direction is predictable. The simplicity of design makes these switches robust, reliable, and cost-effective.

However, paddle flow switches have limitations. They are not suitable for highly viscous fluids, slurries, or fluids containing large amounts of solid particles. Mechanical parts are exposed to wear over time, and accuracy is lower compared to electronic or thermal flow switches. Despite this, their ease of installation and rugged nature keeps them popular in industrial environments.

Thermal Flow Switch

Thermal flow switches operate using heat transfer principles. They typically contain a heated sensor and a reference sensor. When there is no flow, heat remains concentrated around the heated sensor. As flow increases, heat is carried away by the moving fluid. The difference in temperature between the two sensors is measured and converted into an electrical signal.

Key advantages of thermal flow switches include:

- No moving parts

- High sensitivity for low-flow detection

- Ability to detect both gas and liquid flows

- Suitability for clean and corrosive fluids

Thermal flow switches are widely used in:

- Compressed air systems

- Gas pipelines

- Chemical processing

- Semiconductor manufacturing

- Leak detection systems

They are particularly useful for monitoring very low flow rates where mechanical devices fail to respond. Because they have no paddles or mechanical linkages, they require less maintenance and offer a long service life.

However, thermal flow switches can be affected by changes in fluid temperature and thermal conductivity. They also require power to heat the sensor element and may be less accurate in rapidly changing temperature environments. Proper calibration and material compatibility are crucial for reliable operation.

Magnetic Flow Switch

Magnetic flow switches operate based on magnetic field interaction. In one common design, a magnet is mounted on a float or piston inside a flow tube. As fluid flow increases, the float or piston is displaced, bringing the magnet toward a reed switch or Hall-effect sensor. When the switch is actuated, an electrical signal is generated.

Magnetic flow switches are used where:

- Low pressure drop is required

- Non-intrusive monitoring is preferred

- Flow indication is needed in narrow pipelines

Typical applications include cooling systems, lubrication circuits, and small-bore process lines.

The key benefits of magnetic flow switches are:

- Minimal mechanical wear

- High reliability

- Ability to operate with opaque liquids

- Simple signal output integration

They can be designed in both in-line and insertion styles. Unlike paddle switches, they do not require protruding vanes inside the pipeline, making them suitable for sterile or sanitary environments.

However, magnetic flow switches usually work best with clean fluids and may not perform well with high-viscosity or particle-laden liquids. They may also be sensitive to external magnetic interference if not shielded correctly.

Electronic Flow Switch

Electronic flow switches represent a more modern generation of flow monitoring devices. They use advanced sensing elements such as pressure differential sensors, ultrasonic sensors, or Coriolis sensors coupled with microprocessors to measure flow rate and trigger switching outputs.

Electronic flow switches not only detect flow/no-flow conditions but also provide:

- Digital displays

- Analog output signals

- Programmable setpoints

- Diagnostic information

- Communication with PLCs and industrial automation systems

These switches are widely used in:

- Automated manufacturing plants

- Food and beverage processing

- Pharmaceutical production

- Energy management systems

The biggest strengths of electronic flow switches include high accuracy, flexibility, and compatibility with smart-factory environments. Many models support Industry 4.0 protocols and can be integrated into SCADA systems.

On the downside, electronic flow switches are more expensive than basic mechanical designs and may require trained personnel for installation and configuration. They also depend on continuous power availability.

Industrial Flow Sensors

While a flow switch primarily detects whether flow is present or absent (and sometimes whether it is above or below a threshold), industrial flow sensors provide continuous flow measurement. They are often paired with flow switches or integrated within electronic flow switch assemblies.

Industrial flow sensors come in many types, including:

- Ultrasonic flow sensors

- Differential pressure flow sensors

- Coriolis mass flow sensors

- Turbine flow sensors

These sensors measure characteristics such as volume flow rate, mass flow rate, and velocity. They are widely used in refineries, petrochemical plants, water distribution networks, and pharmaceutical systems to maintain precise process control.

In modern industrial systems, flow switches and flow sensors work together. The sensor measures real-time flow data, while the flow switch acts as a safety or control device that triggers alarms or shutdowns when the system deviates from safe operating conditions.

Conclusion

Flow switches are vital safety and control devices in industrial plants. They help protect pumps, boilers, chillers, compressors, and pipelines by detecting abnormal flow conditions.

Different types of flow switches—such as paddle, thermal, magnetic, and electronic—are chosen based on application requirements, fluid characteristics, installation environment, and desired accuracy.

Paddle flow switches offer a rugged, economical choice for straightforward liquid systems.

Thermal flow switches excel in low-flow and gas-flow monitoring, while magnetic flow switches provide reliable, low-maintenance operation.

Electronic flow switches deliver the highest flexibility, smart diagnostics, and automation compatibility.

Complementing all of these are industrial flow sensors, which provide precise measurement needed for advanced process control.

By understanding the capabilities and limitations of each flow switch type, plant engineers and maintenance professionals can select the best solution for safety, reliability, and operational efficiency in industrial environments.