Ever wonder how an oil refinery stays safe, or how a water treatment plant makes sure clean water flows to our homes? The answer often lies with a small but mighty device: the pressure transmitter. These robust instruments are the unsung heroes of industrial processes, working tirelessly behind the scenes to make sure systems run smoothly, reliably, and safely.

So, what exactly is a pressure transmitter? Think of it as a smart measuring device. It checks the pressure of liquids, fluids, and gases in pipes and tanks and then converts that physical measurement into a standard electrical signal. This signal is usually a 4-20mA current or a 1-5 Volt voltage, which can be sent to a remote control system like a PLC. This capability is crucial for monitoring everything from liquid levels and flow rates to filtration systems in vital industries like oil & gas, water treatment, pharmaceuticals, and food/beverage.

In this guide, we’re going to take a friendly tour of the world of pressure transmitters. I’ll walk you through how they work, we’ll explore the different types together, see them in action with some real-world examples, and finish up with a clear checklist to help you choose the right one for your job. Let’s get started!

From Physical Force to Digital Signal: The Science Inside a Pressure Transmitter

At its heart, the pressure transmitter working principle is all about sensing a physical force and translating it into a stable electrical signal that a control system can understand. It might sound a bit complex, but it boils down to three core parts working together perfectly.

The Three Core Components

- Pressure Sensor: This is the primary element that directly senses the process pressure. When exposed to the pressure of a liquid or gas, it experiences a physical change.

- Signal Converter: The initial electrical signal from the sensor is pretty small and wouldn’t travel very far on its own. The signal converter steps in to amplify it and turn it into a standardized, transmittable signal, like that 4-20mA we talked about.

- Transmitter: Finally, the transmitter sends this beefed-up signal to its designated receiver, whether that’s a digital display, an alarm, or the main control system in a distant control room.

A Look at the Measurement Technologies

So, how does the sensor actually feel the pressure? Different transmitters use various cool technologies. Let’s peek under the hood at five of the most common ones:

- Piezoresistive Sensors (The Industry Workhorse): This is the most frequently used technology. It uses a tiny strain gauge made of a semiconductor material (like silicone) attached to a flexible diaphragm. When pressure hits the diaphragm, it stretches the gauge, which changes its electrical resistance. That change corresponds directly to the pressure applied.

- Capacitive Sensors (The Stability Expert): These sensors work like a tiny capacitor, with two parallel plates separated by a small gap. One plate is fixed, and the other is attached to the sensing diaphragm. When pressure moves the diaphragm, the distance between the plates changes, which alters the capacitance.

- Thin Film Resistive Sensors (The Precision Specialist): Imagine a super thin layer of resistive material—we’re talking nanometers thin! When pressure is applied, the resistance of this highly sensitive layer changes, allowing for very precise measurements.

- Optical Sensors (The Interference Fighter): These futuristic sensors use optical fibers. When light passes through the fiber, its properties (like wavelength) change depending on the pressure being applied. By measuring that change, the pressure can be determined accurately. This is great for environments with a lot of electromagnetic noise.

- Hydrostatic Sensors (The Level Measurer): A hydrostatic transmitter is a special submersible pressure sensor that measures the pressure at the bottom of a tank. Its diaphragm is in contact with the liquid on one side and vented to the atmosphere on the other. The pressure it reads is directly proportional to the height of the liquid above it—a clever way to measure levels!.

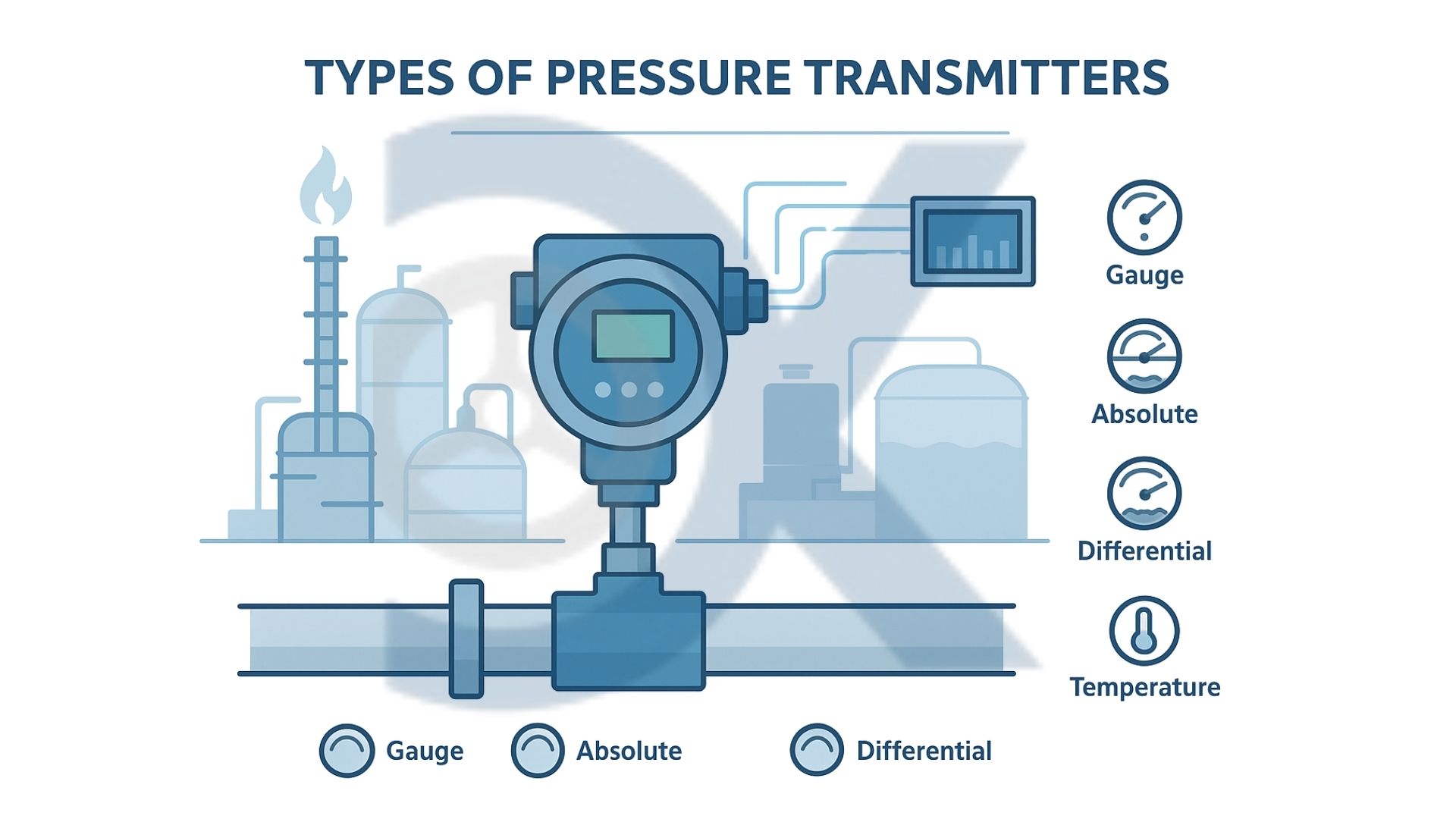

Gauge, Absolute, or Differential? A Guide to the Main Types of Pressure Transmitters

Choosing the right pressure transmitter really comes down to one key question: what are you measuring against? The reference point is everything. Before we jump into the types, let’s quickly get on the same page with our pressure terms:

- Atmospheric Pressure: The pressure of the air all around us, exerted by the gases in the atmosphere.

- Absolute Pressure: Measured against a perfect vacuum, or absolute zero pressure.

- Gauge Pressure: Measured against the local atmospheric pressure.

1. Gauge Pressure Transmitter

Just like its name says, a gauge pressure transmitter measures pressure relative to the surrounding atmosphere. Its sensor has a port connected to the process and another port that’s open to the air. The atmospheric pressure pushes on both sides of an internal diaphragm, effectively canceling itself out, so you’re only left with the gauge pressure.

- Best For: These are the go-to choice in process industries for measuring liquids and gases where you need to monitor pressure against ambient conditions.

2. Absolute Pressure Transmitter

This type measures pressure with respect to a full vacuum. During manufacturing, its reference chamber is sealed at zero pressure. This design is awesome because it’s not affected by changes in atmospheric pressure, which can happen with weather or altitude changes.

- Best For: Any application that demands a very high level of accuracy and can’t be thrown off by atmospheric fluctuations.

3. Differential Pressure Transmitter (The Multitasker)

A differential pressure transmitter, which you might hear called a DP or Delta-P transmitter, does something really cool: it measures the difference in pressure between two points. It has two ports—a “high” side (HP) and a “low” side (LP). A diaphragm sits between them, and any pressure difference causes it to flex.

- Key Advantage: This transmitter is incredibly versatile, making it one of the most popular and rapidly developing types on the market.

- Best For: It’s a champion at measuring flow (by checking pressure across an orifice plate), liquid levels in tanks, and even fluid density.

4. Multivariable Pressure Transmitter

Think of this as the all-in-one smart device. A multivariable transmitter combines differential pressure, absolute pressure, and temperature measurements into a single sensor.

- Best For: It’s especially useful for measuring the mass flow of gases and steam, where all those variables are needed for an accurate calculation.

Beyond the Basics: Smart, Sealed, and Submersible Transmitters

Sometimes, a standard transmitter just won’t cut it. For those tricky situations, there are specialized transmitters designed to handle the challenge.

- Smart Pressure Transmitter: A smart transmitter gives you more control. It has a digital display and keys that let you configure its settings, like the measurement range. For example, you can take a 0-10 bar transmitter and set it to give its full 4-20mA output over a smaller 0-5 bar range. This flexibility is a huge plus in process plants.

- Remote Seal Pressure Transmitter: This is your problem-solver for tough process fluids. It uses a protective interface called a diaphragm seal to keep the sensitive measuring element away from the harsh stuff.

- When to Use It: When your fluid is at a very high temperature; is corrosive, viscous, or contains solids; might freeze or solidify; or is in a hygienic application (like food or pharma) requiring sanitary fittings.

- Submersible (Hydrostatic) Pressure Transmitter: As we touched on earlier, these are designed to be completely immersed in a liquid to measure its level in a tank or reservoir.

- Fixed Pressure Transmitter: This is a compact and straightforward instrument that gets mounted directly on a pipeline. It’s typically powered by 24V DC and gives a 4-20mA output, making it a reliable choice for many applications in the water treatment, pharmaceutical, food, and oil and gas industries.

What About Temperature? Related Instruments You Should Know

In the world of industrial measurement, pressure and temperature are close cousins. You often need to monitor both, and many manufacturers offer a full suite of instruments. While we’re focused on pressure today, it’s good to know about the common temperature transmitter types and related gear:

- Temperature Gauges: Simple and effective, like gas-actuated and bimetal gauges.

- Resistance Temperature Detectors (RTD): A very common and accurate type of temperature sensor.

- Thermocouples: Another popular sensor, available in different types like K & S.

- Thermowells: Think of these as protective armor for RTDs and thermocouples, available in different styles like screwed or flanged to fit any installation.

From Pipelines to Breweries: Where Pressure Transmitters Make a Difference

Pressure transmitters are true workhorses, found in almost every industrial sector you can think of.

Core Industrial Applications:

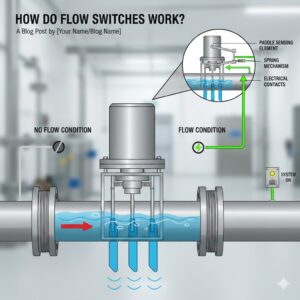

- Flow Measurement: This is one of the most common jobs, especially for a differential pressure transmitter. By measuring the pressure drop across an orifice plate in a pipe, you can calculate the flow rate of the liquid or gas passing through.

- Level Measurement: Whether it’s a huge water tower or a process tank, transmitters are used to measure the fluid level inside. This can be done with a submersible hydrostatic sensor or a DP transmitter.

- Filtration and Leak Detection: Transmitters help keep systems clean by monitoring filters for clogs (by measuring pressure drop). They can also be lifesavers by detecting leaks in pipelines when they sense an unexpected pressure reduction.

Expanding Industry Use:

- Water/Wastewater: From urban water supply to sewage treatment plants, pressure sensors are essential for quality control and system protection.

- Oil & Gas: It’s hard to imagine this industry without them. They are vital for safely handling all kinds of fluids and gases under demanding conditions.

- Food & Beverage / Pharmaceuticals: From brewing and dairy applications to making medicines, transmitters help maintain the precise pressures needed for quality and safety.

- Research & Development: In high-tech fields like automotive and aircraft manufacturing, transmitters are used to measure everything from fuel and air pressure to hydraulic systems.

Don’t Guess, Assess: A 4-Step Guide to Selecting the Perfect Pressure Transmitter

Alright, you’ve learned a ton! Now comes the most important part: choosing the right transmitter for your job. Getting this right is critical for accuracy, safety, and operational efficiency. Just follow these four simple steps:

Step 1: Define Your Fluid and Process Conditions

First things first, get to know what you’re working with. Ask yourself:

- What fluid am I measuring? Is it air, gas, steam, water, or something else?

- What are its characteristics? Think about its density and viscosity, and whether it’s corrosive. This will tell you if you need special materials or a remote seal transmitter.

- What are the operating conditions? You absolutely need to know the pressure and temperature ranges your transmitter will be living in.

Step 2: Determine Your Measurement Goal

Next, what are you actually trying to find out?

- What’s my goal? Are you measuring pressure, flow, level, or density? This is the single biggest step in narrowing down your options.

Step 3: Select the Correct Pressure Reference

Now, let’s go back to our reference points.

- Do I need to measure against the atmosphere? Choose a Gauge transmitter.

- Do I need high accuracy that’s independent of atmospheric changes? Go for an Absolute transmitter.

- Am I measuring a pressure drop between two points? You need a Differential transmitter.

Step 4: Specify the Measurement Range and Dynamics

Finally, let’s talk numbers.

- What’s my pressure measurement range? Define the minimum and maximum pressures the transmitter will need to measure accurately.

- How much does my process vary? This is called “rangeability.” If your process pressure swings wildly, a Smart Transmitter is a fantastic choice because you can configure its range to match your needs perfectly.

Smarter, Smaller, and More Connected: The Future of Pressure Measurement

The technology behind pressure transmitters is constantly evolving. The accuracy of these devices has substantially increased over time, combining improvements in linearity, hysteresis, and repeatability into highly reliable instruments. We’re seeing a clear trend towards more “smart” technology, like transmitters with HART protocol for remote configuration, as well as more compact and integrated designs like multivariable transmitters that save space while providing richer data.

We hope this guide has given you a clear and helpful look into the types of pressure transmitters. They might be small, but their impact on our industrial world is massive.

Ready to find the right pressure transmitter for your needs? Connect with our experts today to get a customized solution!

FAQ’s

What is a pressure transmitter and what is its primary function?

A pressure transmitter is an instrument that measures the pressure of liquids or gases and converts it into a proportional electrical output signal, typically 4-20mA or 1-5V. Its primary function is to transmit this measured pressure signal to a distant control system, like a PLC, for process monitoring and control.

What are the main types of pressure transmitters based on their pressure reference?

The main types are:

• Gauge Pressure Transmitter: Measures pressure relative to the local atmospheric pressure.

• Absolute Pressure Transmitter: Measures pressure relative to an absolute vacuum.

• Differential Pressure (DP) Transmitter: Measures the difference in pressure between two points.How does a differential pressure (DP) transmitter work and what are its common applications?

A DP transmitter has two ports (a high and a low side) with a diaphragm between them. It measures the difference in pressure between the two ports, which causes the diaphragm to flex. This deflection is converted into an output signal. Common applications include measuring fluid flow, liquid level, and density.

What is a remote seal pressure transmitter and when is it used?

A remote seal pressure transmitter uses a protective diaphragm seal to separate the measuring element from the process fluid. It is used when the fluid is at a high temperature, corrosive, viscous, may solidify or freeze, or in hygienic applications requiring sanitary fittings.

What are the key factors to consider when choosing a pressure transmitter?

The key factors are:

• The fluid being measured and its characteristics (density, viscosity).

• The process operating conditions like pressure and temperature.

• The type of measurement needed (pressure, flow, level).

• The required pressure reference (gauge, absolute, or differential).

• The pressure measurement range.