Benefits of Using Indian-Manufactured Industrial Transmitters

India has rapidly emerged as a global hub for industrial manufacturing and automation. With strong engineering talent, modern production facilities, and a growing focus on “Make in India,” Indian companies now produce high-quality industrial transmitters that compete with international brands.

From pressure and level transmitters to temperature and flow instruments, Indian-manufactured industrial transmitters are being adopted across power, water, chemical, oil & gas, pharmaceuticals, and manufacturing sectors.

In this blog, we explore the key benefits of using transmitters made in India, focusing on quality, cost, support, and long-term value for industries.

Industrial Instruments India

The industrial instrumentation market in India has grown significantly over the past decade. Indian manufacturers now design and produce a wide range of industrial instruments in India, including:

- Pressure transmitters

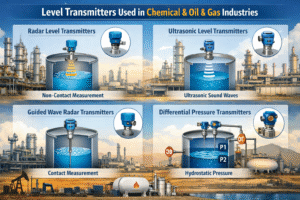

- Level transmitters

- Temperature sensors (RTDs, thermocouples)

- Flow transmitters

- Differential pressure transmitters

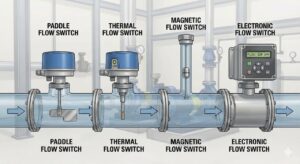

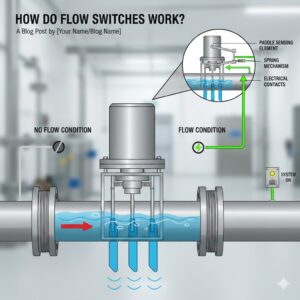

- Control valves and switches

These products are no longer just low-cost alternatives. Many Indian brands follow international standards such as ISO, ATEX, IECEx, and SIL, making them suitable for both domestic and export markets.

Quality and Engineering Strength

Indian instrumentation companies invest heavily in R&D, calibration laboratories, and testing facilities. They use advanced manufacturing techniques such as CNC machining, automated assembly, and digital calibration systems to ensure consistency and accuracy.

With a strong pool of engineers and technicians, Indian manufacturers can also customize transmitters for specific industrial applications such as high temperature, corrosive media, high pressure, or hazardous area use.

Adapted for Indian Industrial Conditions

Industrial environments in India often involve dust, humidity, vibration, heat, and fluctuating power supply. Instruments designed locally are typically built to withstand these conditions better than some imported models, making them more reliable in real-world applications.

Cost-Effective Automation Solutions

One of the biggest advantages of choosing Indian-manufactured transmitters is access to cost-effective automation solutions without compromising performance.

Lower Purchase Cost

Imported instruments often come with high prices due to:

- Import duties

- Shipping costs

- Foreign currency exchange

- Dealer margins

Indian products eliminate most of these extra costs, offering similar technical specifications at a much more affordable price point. This makes automation projects feasible even for small and medium industries.

Reduced Maintenance and Service Cost

Local manufacturing means:

- Easily available spare parts

- Faster repair turnaround

- Lower service charges

- Reduced downtime

Instead of waiting weeks for imported spares, Indian transmitters can often be repaired or replaced quickly, keeping plants operational.

Scalability for Growing Plants

Cost-effective instruments allow plants to scale automation gradually. Industries can start with essential measurements and expand to full automation without massive capital investment.

Local Instrumentation Suppliers

Another major benefit is the presence of strong local instrumentation suppliers across India. These suppliers provide more than just products; they offer technical partnership.

Faster Delivery and Support

Local suppliers ensure:

- Quick delivery

- On-site technical assistance

- Installation guidance

- Calibration support

- Training for plant staff

This is especially important in critical processes where downtime can lead to production loss or safety risks.

Customization and Flexibility

Indian suppliers are more flexible in customizing:

- Pressure ranges

- Process connections

- Output signals

- Housing materials

- Communication protocols

Unlike global brands with fixed catalogs, local manufacturers often adapt products to suit specific project requirements.

Strong After-Sales Network

Most Indian instrumentation companies operate regional service centers and distributor networks, ensuring consistent after-sales support across the country. This builds long-term reliability and trust with industrial users.

Performance and Compliance

Modern Indian-manufactured transmitters are designed to meet global performance standards. Many products comply with:

- ISO quality systems

- ATEX / IECEx hazardous area standards

- SIL safety integrity levels

- IP66 / IP67 ingress protection

- CE marking

This ensures that industries using Indian instruments can operate safely in chemical, oil & gas, power, and pharmaceutical environments without regulatory concerns.

Supporting Make in India and Sustainability

Using Indian-manufactured transmitters supports the Make in India initiative, helping strengthen the domestic industrial ecosystem.

Economic Benefits

- Encourages local manufacturing

- Creates employment

- Develops technical expertise

- Reduces dependency on imports

Environmental Benefits

Local manufacturing reduces carbon footprint associated with international shipping and logistics, contributing to sustainability goals.

Technology and Innovation in Indian Transmitters

Indian manufacturers are adopting advanced technologies such as:

- Smart digital transmitters

- Wireless communication

- HART and Modbus protocols

- IoT-ready instrumentation

- Self-diagnostic features

These innovations help industries integrate transmitters into modern SCADA and Industry 4.0 systems.

Applications Across Industries

Indian-manufactured transmitters are used in:

- Water and wastewater treatment plants

- Chemical and pharmaceutical industries

- Oil & gas facilities

- Power generation

- Food and beverage processing

- HVAC systems

- Steel and cement plants

Their adaptability and cost-effectiveness make them suitable for both small facilities and large industrial complexes.

Choosing the Right Indian Transmitter Supplier

When selecting a local supplier, industries should consider:

- Manufacturing capability

- Certification and compliance

- Calibration facilities

- Technical support strength

- Warranty and service network

- Customization ability

A good supplier becomes a technology partner rather than just a vendor.

Conclusion

The benefits of using Indian-manufactured industrial transmitters extend far beyond cost savings. With improving quality, strong engineering, fast support, and flexible customization, Indian transmitters now match global standards while offering superior value. Industries gain access to cost-effective automation solutions, reliable performance, and responsive service from local instrumentation suppliers.

As automation and digitalization continue to grow across Indian industries, choosing locally manufactured transmitters is not just an economic decision—it is a strategic investment in reliability, sustainability, and long-term industrial growth.