Flow switches are widely used in industrial systems, HVAC units, water pipelines, and fire protection systems to monitor the movement of liquids or gases. Their main role is simple yet critical detecting whether a fluid is flowing and triggering an action or alarm based on that movement. Despite their importance, many people are unclear about how flow switches actually work.

In this blog, we explain how flow switches work, their internal mechanisms, and their real-world applications in a clear and easy-to-understand manner.

1. Flow Switch Working Principle

The flow switch working principle is based on detecting the physical movement of a fluid and converting it into an electrical signal. When fluid flows through a pipe, it exerts force on a sensing element inside the flow switch. Once this force exceeds a preset threshold, the switch changes its electrical state.

In most cases, the switch remains inactive when there is no flow. As soon as flow starts and reaches a specific velocity or pressure, the switch activates and sends a signal to a control system, alarm, or controller.

Key Elements of the Working Principle:

- Presence of fluid movement

- Mechanical or electronic sensing element

- Conversion of motion into an electrical signal

- Triggering of an action or alert

This simple principle makes flow switches highly reliable and widely used across industries.

2. How Flow Switches Operate

To understand how flow switches operate, it helps to look at the step-by-step process during normal operation.

Step-by-Step Operation:

- No Flow Condition:

The fluid is stationary, and the switch remains in its normal (open or closed) position. - Start of Flow:

When fluid begins to move through the pipe, it comes into contact with the sensing element. - Activation Point:

Once the flow rate reaches the preset level, the sensing element moves or reacts. - Signal Output:

The switch changes state and sends a signal to the connected system. - System Response:

The control system performs a programmed action such as activating an alarm, starting a pump, or shutting down equipment.

Flow switches are designed to operate automatically without human intervention, ensuring fast and reliable response.

3. Flow Switch Mechanism

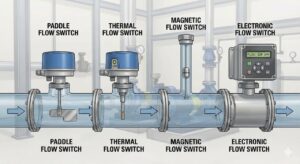

The flow switch mechanism varies depending on the type of flow switch, but the goal remains the same—detect fluid movement accurately.

Common Flow Switch Mechanisms Include:

- Paddle (Vane) Type Mechanism

- Uses a paddle inserted into the flow path

- Flow pushes the paddle, triggering the switch

- Common in water pipelines and HVAC systems

- Piston Type Mechanism

- Uses a spring-loaded piston

- Fluid pressure moves the piston

- Suitable for higher pressure systems

- Thermal Flow Switch Mechanism

- Uses temperature difference caused by flowing fluid

- No moving parts

- Ideal for clean fluids and precise applications

- Magnetic Reed Switch Mechanism

- Uses magnets and reed contacts

- Movement activates the magnetic field

- Provides high reliability and long service life

Each mechanism is selected based on flow rate, fluid type, pressure, and environmental conditions.

4. Flow Switch Function

The primary flow switch function is to confirm whether fluid is flowing or not. However, flow switches serve multiple functional roles depending on the application.

Main Functions of Flow Switches:

- Detect flow or no-flow conditions

- Protect pumps from dry running

- Activate alarms in fire protection systems

- Control equipment such as boilers, chillers, and compressors

- Ensure safe operation of industrial processes

In fire sprinkler systems, flow switches detect water movement caused by an activated sprinkler head and trigger a fire alarm. In HVAC systems, they ensure water or air is flowing before equipment starts operating.

By performing these functions, flow switches improve safety, efficiency, and system reliability.

5. Flow Switch Operation Explained

To further clarify, let’s look at flow switch operation explained using a real-world example.

Example: HVAC Chilled Water System

- When the pump starts, water begins to circulate

- The flow switch detects water movement

- The switch sends a signal confirming adequate flow

- The chiller is allowed to operate safely

If flow stops due to a blockage or pump failure:

- The flow switch deactivates

- The control system shuts down the chiller

- Equipment damage is prevented

Why This Matters

Without flow switches, systems may operate without adequate flow, leading to overheating, equipment damage, or safety risks. Flow switches act as a safeguard, ensuring conditions are correct before allowing equipment to function.

Types of Flow Switches Based on Operation

- Mechanical Flow Switches: Use moving parts like paddles or pistons

- Electronic Flow Switches: Use sensors and microprocessors

- Liquid Flow Switches: Designed for water, oil, or chemicals

- Gas Flow Switches: Designed for air and gases

Each type is designed for specific operating conditions and performance requirements.

Advantages of Using Flow Switches

- Simple and reliable operation

- Fast response time

- Low maintenance requirements

- Improved system safety

- Cost-effective monitoring solution

These advantages make flow switches essential components in many modern

Common Applications of Flow Switches

- Fire sprinkler systems

- HVAC and chiller plants

- Water treatment facilities

- Industrial manufacturing processes

- Pump protection systems

- Cooling towers and boilers

Their versatility allows them to be used in both small-scale and large-scale installations.

Conclusion

Understanding how flow switches work is essential for anyone involved in system design, installation, or maintenance. By detecting fluid movement and converting it into a reliable electrical signal, flow switches help protect equipment, improve efficiency, and enhance safety.

Whether used in fire protection, HVAC systems, or industrial processes, flow switches play a critical role in ensuring smooth and safe operation. Choosing the right type and maintaining it properly ensures long-term performance and reliability.